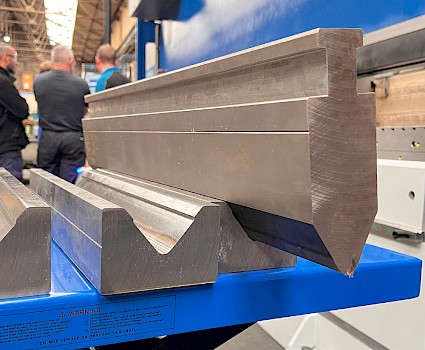

New Rico, 4 metres, 600 tonnes press brake

We have added a new Rico 600 tonnes, 4 metres, PRCB, high performance press brake to our line up.

The new press brake allows us to bend 4 metres 15mm stainless steel plates and 2.2 metres 20mm stainless steel plates. This will improve our range, quality and production of angle brackets and wind posts, which are a common product requested by our customers.

We've also purchased specialist tooling to go with our new machine which means we can press 300 tonnes per metre unlike the standard Euro tooling which will only achieve 100 tonnes per metre.

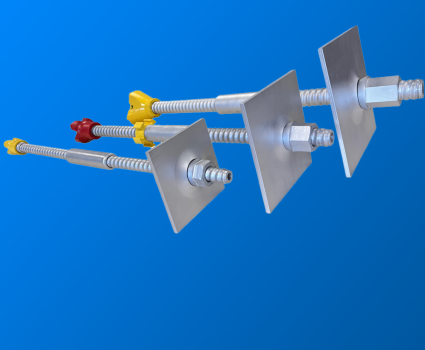

NEW Galvanized Injection Anchors

Our new galvanized injection anchors have been introduced to complement our stainless range. They offer a cost-effective solution, for many inland areas with less corrosive environments. Designed to service the geotechnical and civil engineering sectors. The anchors provide an ideal solution for loose unstable ground with a combination of corrosion resistance and strength.

The system is fully galvanised to BS EN 1461 with a minimum of 85 microns coating thickness potentially extending life to 40-100 years in C3 environments without the need for a corrosion allowance.

The cold formed rope thread to ISO 10208, provides a robust, dirt tolerant thread with good bond characteristics that meet the requirements of BS6744. The cold formed thread improves the characteristics by increasing the tensile properties as well as the fatigue properties.

A wide range of system capacities can be supplied from stock, and non standard fittings and strengths can be produced to order.

Contact our Sales Department to discuss your project requirements. sales@stainless-uk.co.uk 0114 244 1333

In Concrete Timber Connector Project

It's great to see what our customers do with our products! 12 Concrete In post support ordered and this is the outcome! What a lovely design and use of space.

If you require an estimate please fill in this form

Now in Stock 1kg Tying Wire for Dispensers

We now stock 1.2mm, 1kg stainless steel, coils to go along side our 20kg coils. They have a 44mm inner diameter so can be used in a mobile dispenser which can be attached to your belt. The coil is soft annealed so it is not as brittle as other trying wire. The tying wire reels are used for connecting stainless steel rebar and rebar mesh panels in construction.

Westonbirt Arboretum Community Coppice Shelter

In Spring 2022 we manufactured a set of very unique timber connectors for Xylotek Ltd, who were working on a community Shelter project in Westonbirt Arboretum, for Forestry England. Our standard timber connectors are usually made square with a shoe set at a 90 degree vertical pitch but the specification for this project required a range of connectors with parallelogram bases, custom pitches, on a skew. To overcome the acute angles instead of bending the shoes on a press brake we ended up setting our experienced welding team to the task.

The previous community shelter had to be dismantled in 2017 as it was no longer fit and safe to be used but the need for a community shelter was still necessary. In winter 2021 that architect Piers Taylor from Invisible Studio and engineers from Format Engineers got together with Forestry England and Friends of Westonbirt Arboretum to create this amazing new community shelter.

The shelter was designed to be more than just a functional building but one that fits aesthetically into the landscape. The structure is made from a combination of sustainable and recyclable materials, the oak frame being sourced from the mill in Silk Wood where the shelter is situated.

Xylotek was contracted to fabricate the oak lath gridshell made up of a series of complex arches and bracing. The arches and frame work are fixed to the ground with 9 custom timber connectors, supplied and manufactured by our team at Stainless UK.

While our contribution is small in part, we are still very proud and thankful to be part of such an amazing project.

Photos by Martin Phelps

Grip Bar Emergency works at Skomer Island

Stainless UK has manufactured and supplied Injection Anchor and Grip Bar for emergency works to secure a landslide above the primary access slipway to the Island. Installation was completed by Colin Jones Rock Engineering ahead of schedule before the restrictive impending nesting and eco-tourism season.

Skomer Island, is a world renowned Wildlife Trust less than a mile off the Pembrokeshire coast. The island is home to a vast range of wildlife which live in the exposed headlands, towering offshore rocks, and sheltered inlets. At 730 acres, Skomer is the largest of Pembrokeshire’s islands. It is owned by Natural Resources Wales and managed by The Wildlife Trust of South & West Wales.

Stainless UK specialises in the manufacture of stainless steel anchor bars and tie bars for use in coastal reinforcement, repair and renovation.

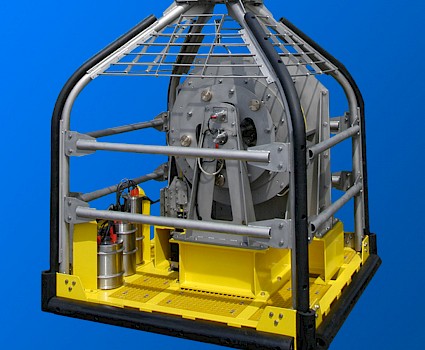

Stainless UK dives in the deep sea with Datem

Datem are one of the world leaders in CPT systems (cone penetration test). Their units are used for acquiring the properties of the soil, cable routes and gas pipelines under the sea. Sometimes this can be up to 3000 metres below sea level. The majority of the components for their products are made from stainless steel and we at Stainless UK manufacture and supply the back plate for both the Neptune 3000 and Neptune 5000 systems.

The two grades of stainless steel that we normally use in our manufacturing process are 304 and 316. In this project stainless steel grade 316 is the choice as it has a higher corrosion resistance and so is suitable in salt water applications. The main difference between the two grades is the presence of molybdenum and increased nickel content in grade 316 both improve the resistance.

Stainless 304 consists of 18% chromium and 8% nickel.

Stainless 316 consists of 16% chromium, 10% nickel and 2% molybdenum.

Stainless UK become official stockist of Fischer Fixings

We are delighted to announce that we are now an official stockist of Fisher Fixings, complementing our custom stainless steel fabrication service.

Fischer Fixings are recognised in the industry for their quality and they are often specified on the parts lists for orders. We look forward to working with Fischer Fixings to provide a complete fabrication package for your needs.

For a full range of thier products please visit https://www.fischer.co.uk/en-gb/

Sunset House, St. Ives gets stainless injection anchor solution.

Sunset House, Situated directly on the Cliff edge, is one of St Ives most iconic properties. A landslip had occurred during the construction phase of this residential building. Georats Ltd. were contracted to design and install slope stabilization.

The solution was to install 110 injection anchors up to 6m deep with a diameter of 90mm. Stainless UK supplied R32 marine grade 316 hollow injection anchors which were install to the full 6m depth and then grouted down hole. Finally 32 tonnes of shotcrete was hand sprayed onto the slope to a minimum thickness of 150mm

Images have been kindly supplied by Georats

Stainless UK Install 10 KW Fiber Laser

Stainless UK are proud to announce they have installed the first ever Esprit 10KW Fiber Laser Cutting Machine. The state of the art machine will sit alongside their existing 6kw Laser and will not only support them with the increased demand of their fabrication services it will also expand their capability.

The new Fiber Laser Cutting CNC machine will reduced production times with it's staggering vector speeds of 325m/min. The machine will also cut 30mm stainless steel plate and create precision cuts and holes down to 2.5mm, further increasing the services that Stainless UK can offer their customers.

Stainless UK join UKCSA

Stainless UK have become associate members of UKCSA.

UKCSA was formed as an independent trade association to increase specifiers’ and contractors’ awareness and confidence in cast stone and to establish and maintain the highest standards of product quality and usage

Stainless UK produce stainless steel reinforcement bar and mesh and fabricate bracketry and windposts used in the construction of building facades.

As an associate member to UKCSA our products conform and meet the criteria that is required.

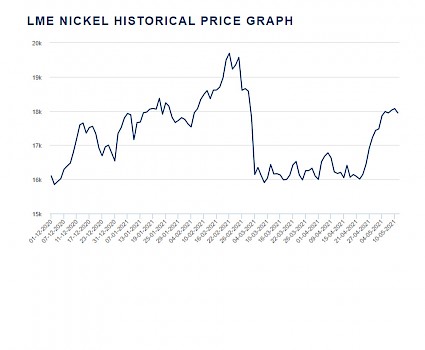

Nickle Price Increase

The price of Nickel dropped earlier this year to $16000 (March 2021) just after it reached it’s all time high of almost $20000 a tonne. Since then it’s been sitting in the $16000’s until this week when it jumped up almost $2000 a tonne. This most recent price spike puts it back on it’s steady increase since early 2020.

Stainless steel production uses over two thirds of the global Nickel supply and so the cost of Nickel directly impacts the cost of Stainless Steel. Nickel is an alloying element which improves the formability and weldability of stainless steel while increasing it’s corrosion applications. Grade 304 contains 8% and grade 316 11% .

As a stockholder of stainless steel and manufacture of stainless steel products we are always monitoring the value of stainless so that we can give the best value of products to our customers.

Stainless UK Move into New Factory and Offices

Stainless UK have moved into an new factory and offices on their Newhall Road Works site. With over 50% more production space and newly refurbished offices the move will allow the company to better deal with the increased demand for their of civil engineering products.

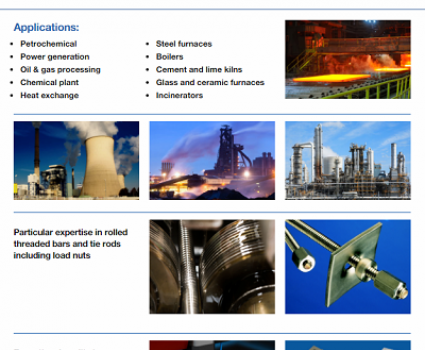

Stainless UK Launch New Heat Resistant Steels Website

Stainless UK have launched a new website featuring Heat Resistant Steels. A wide range of bar and plate is available in austenitic and nickel alloy grades.

New Stainless UK Products Literature

Stainless UK have launched a new product brochure covering all their range of stainless steel products for civil and geotechnical engineering. This provide specifiers and contractors with detailed information on the company's product range and help select the best product for a each project.

Stainless UK Install New CNC Press Brake

With increased demand for their stainless steel fabricated products, Stainless UK have invested in an additional CNC press brake. The 150t machine will accurately bend stainless steel sections up to 3m long for use in commercial and civil engineering projects

New Project Guide From Stainless UK

Stainless UK have supplied many interesting and challenging projects with their stainless steel Grip-Bar, Injection Anchor and Reinforcing Bar products. To showcase some of these projects the company has published a new updated brochure giving details of how their products have been used on projects as diverse as coastal defence, bridges and historic buildings.

Stainless UK Increase Their Manufacturing Space

Stainless UK have taken additional manufacturing space at their Newhall Road Works site to allow the company to expand its operations. The move will allow the creation of a dedicated unit for their Grip-Bar and reinforcing bar products and also create additional space in their existing factory to expand the company's fabrication facilities.

Additional CNC Lathe for Stainless UK

An additional CNC lathe has been purchased by Stainless UK to help increase output of fixings for the company's Grip-Bar product range. Grip-Bar is a unique fully threaded stainless steel anchor and tie bar system. All Grip-Bar load nuts, lock nuts and couplers are made in-house to exacting standards to ensure full strength integrity when in use.