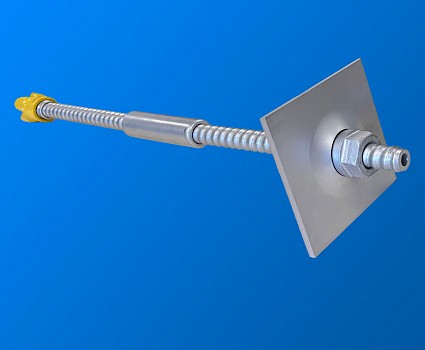

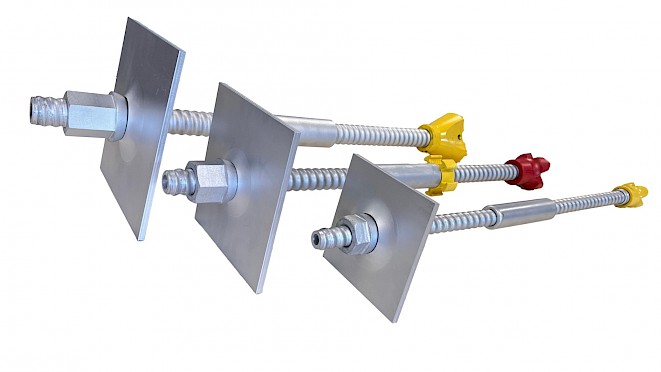

Galvanised Injection Anchor

Stainless UK’s self drilling hollow bar system is a fully threaded self drilling system that can be installed into loose ground conditions without the need for casing. While stainless systems will be far superior in terms of corrosion resistance in many less aggressive conditions galvanised systems will offer a more cost effective solution..

UNIVERSAL SIZES FOR COMPATIBILITY

- The bars are fully threaded with a cold rolled ISO standard left hand rope thread compatible with most drilling rigs.

- Bars can be supplied in stock lengths and cut to length on site, or in shorter lengths to allow ease of handling.

- Long life structures

APPLICATIONS

- Embankment stabilisation

- Coastal defence walls, slopes and slabs

- Marine and aggressive environments

- Mining and tunnelling

- Rock bolts

- Retaining walls

- Structures in seismic areas

LOAD BEARING COMPONENTS

Couplers are designed to transfer the system load, with a central shoulder to ensure the end faces of the bars fully bear on each face and thread lengths are designed to transfer the full load in tension.

Nuts designed to transfer the full load of the end plate into the hollow bar. Nuts can be supplied with a domed end to be used with a dished plate to allow for misalignment or as a standard hexagon to be used with a flat plate.

Plates can be supplied to suit individual project requirements and will be dependent on application and ground conditions.

Stainless UK Galvanised Hollow Bar Product Data |

||||||||||

| Product | Model | Nominal Dia. (mm) |

Stock Length* (mm) |

Nom.Outer Dia. (mm) |

Internal Dia. (mm) |

Ultimate Tension Capacity (kN) | Yield Tension Capacity (kN) | A elongation (%) |

Agt (%) |

Weight (kgs/m) |

| Hollow Bar | R25 | 25 | 1500 & 3000 | 24.7 | 14 | 200 | 150 | ≥8% | ≥5% | 2.35 |

| R32N | 32 | 31.3 | 18.5 | 280 | 230 | 2.95 | ||||

| R32S | 32 | 31.3 | 15 | 360 | 360 | 3.50 | ||||

| R32S1 | 32 | 31.3 | 12 | 405 | 405 | 4.00 | ||||

| R38N | 38 | 38 | 19 | 500 | 500 | 4.95 | ||||

| R38S | 38 | 38 | 15 | 550 | 550 | 5.90 | ||||

*Other Lengths are available on request

Fittings |

||||

| Product | Size | Outer Dimension (mm) |

Length (mm) | Weight (Kgs) |

| Coupler | 25 | Ø36 | 150 | 0.66 |

| 32 | Ø42 | 190 | 1.01 | |

| 38 | Ø51 | 220 | 1.68 | |

| Full Nut | 25 | 41 (A/F) | 40 | 0.31 |

| 32 | 46 (A/F) | 45 | 0.37 | |

| 38 | 50 (A/F) | 60 | 0.47 | |

| Domed Nut | 25 | 41 (A/F) | 40.5 | 0.31 |

| 32 | 46 (A/F) | 45 | 0.38 | |

| 38 | 52 (A/F) | 60 | 0.61 | |

| Product | Size | Dimensions (mm) |

Thickness (mm) |

Weight (Kgs) |

| Domed Plate | 25 | 200 x 200 | 10 | 2.94 |

| 32 | 200 x 200 | 12 | 3.52 | |

| 38 | 200 x 200 | 12 | 3.6 | |

| Product | Size | Outer Dimension (mm) |

Length (mm) | Weight (Kgs) |

| Wedge Boss | 25-38 | 122 | 70 | 1.00 |

Drill Bits |

||||

| Size | Type | Outer Dia (mm) |

Description | Typical Applications |

| SSR32/51 | EXX | 51 | Cross Bit with Tungston Carbide Inserts | Softer sedimentary rocks such as marls, mudstones, siltstone |

| SSR32/76 | EXX | 76 | ||

| SSR38/76 | EXX | 76 | ||

| SSR38/100 | EXX | 100 | ||

| SSR38/130 | EXX | 130 | ||

| SSR32/51 | ES-F | 51 | Hardened Steel Button Bit | Gravel, soft rock |

| SSR32/76 | ES-F | 76 | ||

| SSR38/76 | ES-F | 76 | ||

| SSR38/90 | ES-F | 90 | ||

| SSR38/115 | ES-F | 115 | ||

| SSR32/51 | ESS-F | 51 | Hardened Steel Button Bit with Tungston Carbide inserts | Weathered rock, stone walls, rubble |

| SSR32/76 | ESS-F | 76 | ||

| SSR38/76 | ESS-F | 76 | ||

| SSR38/90 | ESS-F | 90 | ||

| SSR38/115 | ESS-F | 115 | ||

Accessories |

||||

| Product | Size | Outer Dia (mm) |

Length (mm) |

Weight (kg) |

| Adaptor Sleeve | 25/32 |

32 |

50 | 0.10 |

| Centraliser | 32 | 72 | 30 | 0.27 |

| 38 | 78 | 30 | 0.28 | |

SITE PERFORMANCE

Injection anchors are produced using a cold rolled thread which not only enhances the strength of the bar, but also provides a self cleaning, robust thread which is easy to use on construction sites. The ISO standard rope thread, which is continuous along the length of the bar, permits site cutting of the bar without the need for special tools or dressing procedures, whilst also fitting the majority of rock drilling machines.

BOND

The bond of the injection anchor is in accordance with BS 8110 and BS 6744, the continuous thread provides a key for the grout.

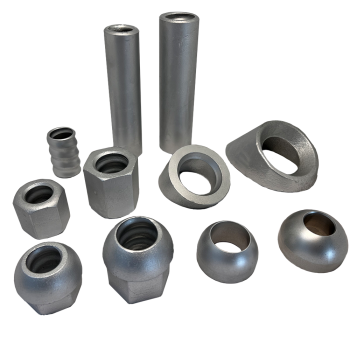

System Accessories

Galvanised injection anchors can be supplied with a range of accessories, which can be manufactured to meet individual contract requirements.

The selection of any drill bit is based on experience, but a trial anchor must be satisfactorily tested before the project is finally commenced.

SACRIFICIAL DRILL BITS

Drill bits to suit all applications and ground conditions.

PLATE WASHERS

Manufactured either flat which can take up to 8 degree misalignments or dished to suit up to 45 degree misalignment. Can be supplied with a hemi nut or washer to suit.

REDUCER WASHER

Allows a small diameter bar to be used with a larger pattress or washer plate.

COUPLERS / NUTS

Load nuts and couplers have been designed to provide a strength of anchorage equal to the theoretical minimum required by the threaded bar. Lock nuts are for locking purpose only

EYE NUT

To be fitted to the end of the bar for passing rock netting wire through and many other uses.