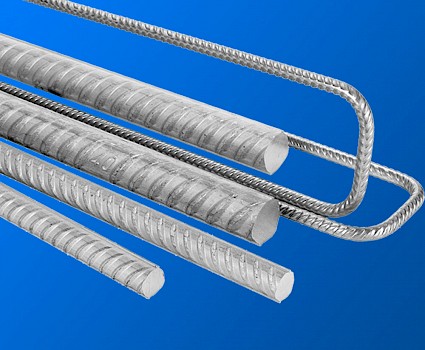

Rebar

Stainless UK are CARES approved for processing stainless steel reinforcing bar. Bars are available bent according to the shape codes given in BS 8666.

The excellent corrosion resistance of Stainless Steel Rebar when used in roads, bridges, buildings and marine environments eliminates the risk of structural damage due to rust.

Consequently reducing lifetime costs significantly.

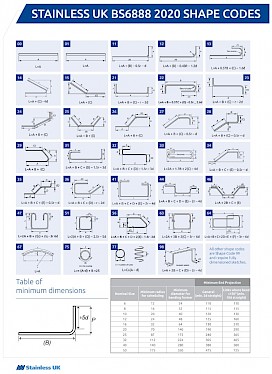

BS8666:2020 Shape Codes

In January 2021, the British Standard used to describe the scheduling, bending and cutting of reinforcement bar was updated to BS8666:2020. The previous standard was BS8666:2005.

There are quite a few significant changes which affect how the total length of bars are calculated as well as some additional shape codes.

Click on the image to view a larger version of the BS8666:2020 Shape Codes

Stainless UK are CARES approved for processing stainless steel reinforcing bars

- Standard stainless steel reinforcing bar (rebar) diameters range from 6mm to 40mm

- Stock lengths vary from 6.0 to 6.1m and bars can be supplied cut to any length.

The three grades of stainless steel reinforcing bar held in stock are:

- Stainless steel grade 304 (1.4301) Ribbed bar (Rebar) suitable for most atmospheric and concrete covered environments.

- Stainless steel grade 316 (1.4436) Ribbed bar (Rebar) recommended grade for marine and corrosive environments.

- Stainless steel duplex grade (1.4362) Ribbed bar (Rebar) recommended grade for marine and corrosive environments.

The strength characteristics for stainless steel rebar are Proof Strength - 500 N/mm², Ultimate Tensile Strength - 550 N/mm², Elongation - 14%

Optional extras

- Bars can be bent according to the shape codes given in BS 8666.

- Threaded ends with ISO metric threads to BS 3643 can be supplied for fixing applications.

- A full range of accessory products are available including square backing plates, nuts, washers, tying wire, end caps and de-bonding sleeves.

When compared with the costs associated with the use of carbon steel, stainless steel can reduce total lifetime costs significantly.

|

GRADES OF REBAR READILY AVAILABLE WITHIN BS 6744 |

|||||

|

Key:

|

|||||

| Grades in accordance with BS EN 10088-1 | Readily Available Rebar Grade | For structures or components with either a long design life, or which are inaccessible for future maintenence | For structures or components exposed to chloride contamination with no relaxation in durability design [e.g. concrete cover or water proofing treatment requirements] | Reinforcement bridging joints, or penetrating the concrete surface and also subject to chloride contamination [e.g. dowel bars or holding down bolts.] | Strucures subject to choloride contamination where reductions in normal durability requirements are proposed [e.g. reduced cover, concrete quality or ommission of water proofing treatment] |

| 1.4301 [304]* | x | 1 | 1 | 5 | 3 |

| 1.4311 | 1 | 1 | 5 | 3 | |

| 1.4436 [316]** | x | 2 | 2 | 1 | 1 |

| 1.4429 | 2 | 2 | 1 | 1 | |

| 1.4362*** | x | 2 | 2 | 1 | 1 |

| 1.4462 F51 | 2 | 2 | 1 | 1 | |

| 1.4529 | 4 | 4 | 4 | 4 | |

| 1.4501 F55 | 4 | 4 | 4 | 4 | |

THREADED ENDS

Stainless UK can supply bar with threaded ends for fixing applications to suit customer requirements. The ends are threaded with ISO metric threads to BS 3643.

REBAR COUPLERS

Manufactured to meet the minimum strength of threaded Rebar.

*1.4301 (304) rebar, the fixings are available in the matching grade.

**1.4436 (316) rebar, the fixings will be supplied in grade 1.4404 (316).

***1.4362 (Duplex) rebar, the fixings will be supplied in grade 1.4462 (Duplex) or 1.4404 (316).

please check suitability with your design engineer before specifying.

| Bar Dia [mm] | Bar | Coupler | ||

| Thread Size | Threaded Length [mm] | Diameter [mm] | Length [mm] | |

| 12 | M 12 | 17 | 18 | 37 |

| 16 | M 16 | 21 | 25 | 45 |

| 20 | M 20 | 25 | 30 | 53 |

| 24 | M 24 | 30 | 33 | 63 |

| 32 | M 30 | 37.5 | 42 | 81 |

| 40 | M 39 | 50 | 60 | 107 |

SIZES AND STRENGTHS

| REBAR 500 PROOF - 550 UTS | |||||||

| Unthreaded | Threaded | ||||||

| Ref | Kg/m | Cross Section Area [mm²] | Ultimate tensile load kN | Proof load 0.2% N/mm kN | Metric Threaded Size | Ultimate tensile load kN | Proof load 0.2% N/mm kN |

| RB 5 | 0.155 | 19.6 | 10 | 9 | |||

| RB 6 | 0.224 | 28.3 | 15 | 14 | M6 | 12 | 11 |

| RB 8 | 0.397 | 50.3 | 27 | 25 | M8 | 21 | 17 |

| RB 10 | 0.620 | 78.5 | 43 | 39 | M10 | 34 | 31 |

| RB 12 | 0.893 | 113.1 | 62 | 56 | M12 | 50 | 45 |

| RB 16 | 1.589 | 201.1 | 110 | 100 | M16 | 91 | 82 |

| RB 20 | 2.482 | 314.2 | 172 | 157 | M20 | 143 | 130 |

| RB 25 | 3.878 | 490.9 | 269 | 245 | M24 | 207 | 188 |

| RB 32 | 6.353 | 804.2 | 442 | 402 | M30 | 327 | 296 |

| RB 40 | 9.927 | 1256.6 | 691 | 628 | M39 | 570 | 517 |

| RB 50 | 15.512 | 1963.5 | 1079 | 981 | M48 | 859 | 777 |

Metric Threaded Rebar

Threaded Metric ends available on request

SAFETY END CAPS

Used to cover the ends of exposed cut Rebar and Dowel Bar to prevent injuries on-site. (Also known as mushroom caps)

DOUBLE LOOP TIES

Stainless steel double loop ties and wire binder tool.

MESH

Mesh is manufactured with tolerances within BS8666. Material is within BS6744.

NUTS AND COUPLERS

Load nuts and couplers have been designed to provide a strength of anchorage equal to the theoretical minimum required by the threaded bar. Lock nuts are for locking purposes only.