Stainless UK dives in the deep sea with Datem

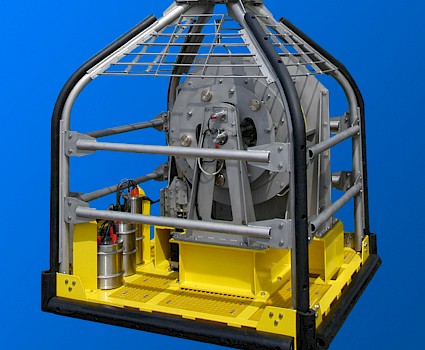

Datem are one of the world leaders in CPT systems (cone penetration test). Their units are used for acquiring the properties of the soil, cable routes and gas pipelines under the sea. Sometimes this can be up to 3000 metres below sea level. The majority of the components for their products are made from stainless steel and we at Stainless UK manufacture and supply the back plate for both the Neptune 3000 and Neptune 5000 systems.

The two grades of stainless steel that we normally use in our manufacturing process are 304 and 316. In this project stainless steel grade 316 is the choice as it has a higher corrosion resistance and so is suitable in salt water applications. The main difference between the two grades is the presence of molybdenum and increased nickel content in grade 316 both improve the resistance.

Stainless 304 consists of 18% chromium and 8% nickel.

Stainless 316 consists of 16% chromium, 10% nickel and 2% molybdenum.