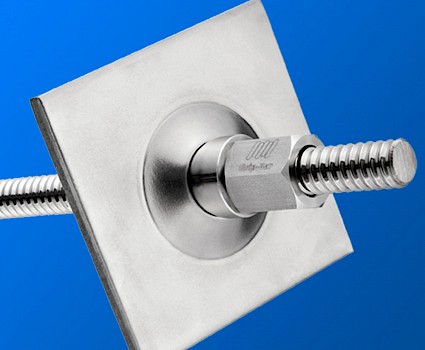

Grip-Bar

A corrosion resistant anchor bar, Grip-Bar® is a unique high bond, high strength Stainless Steel threaded bar for Rock Anchors, Soil Nails, Masonry and Concrete Fixing. The Grip-Bar® Anchor System has been developed to service Civil Engineering and Geotechnical applications.

BENEFITS

- High strength thread rolled stainless steel bars

- Fast thread bar with self cleaning thread

- Proven high bond strength

- Easily cut on site without any damage to thread form

- Unique corrosive resistant product

- 6 metre standard lengths

- Can be cut or joined to size

- Superior ductility for seismic activity

APPLICATIONS

- Rock bolts

- Soil nails

- Building and bridge cross ties

- Ground anchors

- Holding down bolts

- Coastal defence walls, slopes and slabs

- Ancient monuments

- Docks and harbours

| Ref | Nom. Dia. | C.S.A | 0.2% proof load | Ultimate tensile load | Weight per metre |

| mm | mm² | kN | kN | Kg/m | |

| GB10 | 10 | 62 | 40 | 46 | 0.49 |

| GB12 | 12 | 91 | 54 | 64 | 0.73 |

| GB16 | 16 | 167 | 108 | 124 | 1.30 |

| GB20 | 20 | 261 | 170 | 196 | 2.10 |

| GB22 | 22 | 322 | 203 | 235 | 2.60 |

| GB24 | 24 | 378 | 246 | 283 | 2.90 |

| GB27 | 27 | 492 | 320 | 368 | 3.90 |

| GB30 | 30 | 596 | 388 | 446 | 4.70 |

| GB33 | 33 | 737 | 480 | 552 | 5.75 |

| GB36 | 36 | 873 | 568 | 653 | 7.00 |

| GB39 | 39 | 1037 | 674 | 776 | 8.25 |

| GB42 | 42 | 1197 | 778 | 896 | 9.50 |

| GB45 | 45 | 1388 | 903 | 1038 | 10.90 |

| GB48 | 48 | 1562 | 1016 | 1168 | 12.40 |

MANUFACTURING PROCESS

The high strength Grip-Bar® is made from cold drawn bar feedstock. It benefits from superior strength, whilst retaining the elevated ductility associated with stainless steel. Grip-Bar® is manufactured in 6m fully threaded lengths or by special order, with a bespoke thread on the ends of the bar. All the Grip-Bar® range of threaded products utilise the thread rolling principle, which benefits from not removing any material from the bar whilst generating the coarse thread. It is in principle a cold forming process, and hence the grain flow caused by this process improves the fatigue strength of the thread relative to that of a cut thread of the same size.

CORROSIVE CONSIDERATIONS

The selection of the correct grade of stainless steel must take account of the following features

-

The environment

-

Structural requirements

-

Maintenance

-

Life of structure

-

Surface finish

Factors, which may influence the selection within an environment, are temperature, pollutants, humidity and presence of chloride ions. The strength of the bar to be used is a structural matter to be decided by the project designer. In general it is reasonable to use grade 304 for most non-marine applications, however highways and marine structures generally call for grade 316 because of high chloride concentrations. Duplex grade 1.4462 can be used in high chloride environments for increased resistance to stress corrosion, pitting and crevice corrosion.

BOND

The development of the Grip-Bar® thread has over the years been supported by research, both by Stainless UK and at the University of Sheffield. Bond tests in accordance with BS 8110-type 2 bond reinforcing bar have shown that the Grip-Bar® thread provides a bond well in excess of that required.

Further research has been completed to investigate the performance of Grip-Bar® in a rock bolting environment with varying free and bonded lengths.

On each occasion the performance significantly out performed reinforcing bar comparators and both systems are in excess of the codes minimum recomendations.

SITE PERFORMANCE

Grip-Bar® is produced using a cold rolled thread which not only enhances the strength of the bar, but also provides a robust, self cleaning and user friendly thread which is easy to use on construction sites. The coarse pitch thread is less susceptible to galling than the traditional metric thread; the large pitch significantly speeds up assembly. The large flank angle on this bespoke thread design ensures that the crown of the thread is supported and will withstand significant site abuse and still remain serviceable.

SITE STRESSING

We do not recommend using torque to give a given load in a bar. The effects of friction are such that using torque is so unreliable as to make it impractical.

To accurately apply a given load kN to a bar, hydraulic jacking equipment is required.

Jacks are available with gauges calibrated against a certified load cell to register a given force exerted on the bars.

There are various companies who specialise in this process.

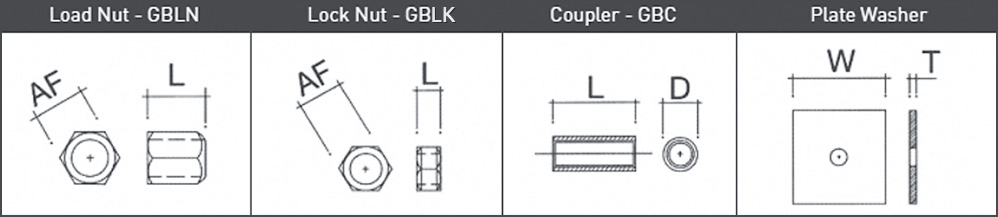

FITTINGS

All the fittings have been designed to provide a strength of anchorage equal to the theoretical minimum required by the threaded bar.

Fittings are made as small as possible to ensure that the strength of the Grip-Bar® can fully be utilised, by selecting the smallest cored hole for the application, saving on drilling time, reducing the size of drilling plant required, both resulting in the optimum cost solution.

Couplers, load nuts and lock nuts are stocked in grade 316 stainless steel only.

| GB Dia | Load Nut - GBLN | Lock Nut - GBLK | Coupler - GBC | Plate Washer | GB Dia | ||||||||

| AF | Length | Weight | AF | Length | Weight | Dia. | Length | Weight | Width | Thickness | Weight | ||

| mm | mm | Kg | mm | mm | Kg | mm | mm | Kg | mm | mm | Kg | ||

| GB10 | 17 | 18 | 0.02 | 17 | 9 | 0.01 | 19 | 41 | 0.06 | 100 x 100 | 8 | 0.62 | GB10 |

| GB12 | 19 | 20 | 0.03 | 19 | 10 | 0.02 | 19 | 51.5 | 0.07 | 100 x 100 | 8 | 0.62 | GB12 |

| GB16 | 24 | 26 | 0.06 | 24 | 13 | 0.03 | 25 | 64 | 0.14 | 100 x 100 | 8 | 0.62 | GB16 |

| GB20 | 30 | 32 | 0.12 | 30 | 16 | 0.06 | 30 | 76 | 0.23 | 125 x 125 | 10 | 1.22 | GB20 |

| GB22 | 36 | 35 | 0.23 | 36 | 17 | 0.12 | 33 | 85 | 0.32 | 150 x 150 | 10 | 1.74 | GB22 |

| GB24 | 36 | 38 | 0.21 | 36 | 19 | 0.11 | 36 | 91 | 0.41 | 150 x 150 | 10 | 1.74 | GB24 |

| GB27 | 42 | 44 | 0.35 | 42 | 23 | 0.18 | 41 | 104 | 0.69 | 150 x 150 | 10 | 1.74 | GB27 |

| GB30 | 46 | 48 | 0.45 | 46 | 24 | 0.22 | 45 | 107 | 0.79 | 200 x 200 | 12 | 3.75 | GB30 |

| GB33 | 50 | 60 | 0.65 | 50 | 27 | 0.29 | 50 | 115 | 1.07 | 210 x 210 | 15 | 5.20 | GB33 |

| GB36 | 56 | 66 | 0.93 | 56 | 29 | 0.41 | 55 | 122 | 1.34 | 225 x 225 | 20 | 7.99 | GB36 |

| GB39 | 60 | 68 | 1.08 | 60 | 32 | 0.51 | 59 | 130 | 1.67 | 250 x 250 | 20 | 9.87 | GB39 |

| GB42 | 65 | 70 | 1.32 | 65 | 34 | 0.64 | 64 | 137 | 2.04 | 250 x 250 | 20 | 9.87 | GB42 |

| GB45 | 70 | 72 | 1.58 | 70 | 36 | 0.79 | 68 | 145 | 2.48 | 300 x 300 | 30 | 21.42 | GB45 |

| GB48 | 75 | 76 | 1.93 | 75 | 38 | 0.96 | 73 | 152 | 2.95 | 300 x 300 | 30 | 21.42 | GB48 |

COMPARISON OF GRIP-BAR® AGAINST THREADED REINFORCEMENT BAR

Traditional methods of rock anchoring have involved the use of reinforcement bar with a threaded section. This system has suffered from a number of disadvantages which the use of Grip-Bar® helps overcome.

- TENSILE STRENGTH

- Reinforcement bar to BS 6744 has a proof strength of 500N/mm². To produce a thread on this bar requires reducing the bar section with a consequent reduction in strength. Grip-Bar® is manufactured from bar with a proof strength of around 600N/mm² which after being work hardened by thread rolling gives a minimum proof strength of 650 N/mm².

- BOND STRENGTH

- Comparative testing carried out by the University of Sheffield has shown that across a range of grout strengths, Grip-Bar® has bond strength up to first slip of at least 2.8 times that of equivalent reinforcement bar.

- THREAD STRENGTH

- Threading a reinforcement bar involves cutting a fine thread into the material which disrupts the surface and can make installing fixings more difficult. The course thread on Grip- Bar® is cold rolled which hardens the surface making fixings easier to apply.

- FLEXIBLE INSTALLATION

- With reinforcement bars, the threaded end has a fixed specified length. Variations on site may require changes to embedment length. This requires reforming the thread off site causing delays and possible thread damage. Grip-Bar® is fully threaded and can but cut to length on site without damage.

NUTS AND COUPLERS

Load nuts and couplers have been designed to provide a strength of anchorage equal to the theoretical minimum required by the threaded bar. Lock nuts are for locking purposes only.

TURNBUCKLE

To be used for adjusting the tension or length of a bar system.

LANTERN SPACERS

Centralisation of a single bar within a bore hole enables an even flow of grout around the bar.

GRIP SOCK

A flexible sock which fits over the anchor bar. As it is filled with grout it expands into cracks and holes.

Pattress Plate

Pattress plates are designed to provide low-bearing stress on buildings, bridges, and retaining walls. When used with Grip-Bar® anchors they form an effective repair system.

Dished Plate Washer

Dished Plate Washers supplied with a hemispherical washer. The plates are pressed centrally to provide a misalignment of up to 40 degrees.